| Availability: | |

|---|---|

Our FAB 2 Type Thick Turret Tooling is a cutting-edge product that represents the latest advancements in metalworking tooling technology. It has been developed to meet the growing demands of the industry for more efficient and reliable solutions for processing thick metal sheets. The tooling features a sleek and compact design that maximizes its performance while minimizing its footprint on the production floor. The components are made from premium-grade materials that offer excellent resistance to wear, corrosion, and heat. The FAB 2 Type Thick Turret Tooling is designed to work seamlessly with a variety of turret punch press models, providing a versatile and cost-effective solution for metalworking businesses.

The FAB 2 A-Station Tooling (originally known as the NEX 3 style) is an ultra-high-efficiency, small-diameter punch assembly designed for holes up to 0.500" (12.7mm). The "FAB 2" designation signifies the third generation of this quick-change technology, focusing on extreme speed, tool-less adjustment, and extended life for high-volume production.

1. Core Design: The Integrated Power Head

The FAB 2 A-Station is a "canister-style" tool where the punch, spring, and driver are merged into a single, high-performance unit.

*Compact Spring Pack: It utilizes high-tension coil springs designed for high-frequency hit rates (exceeding 1,000 hits per minute).

*Hardened Guide Body: The assembly features a precision-ground, fully hardened guide that protects the turret bore while providing a "near-zero" tolerance fit for the punch, ensuring maximum hole accuracy

2. Advanced Adjustment Mechanism

The most significant feature of the FAB 2 style is the Internal Click-Adjust system, which replaces traditional shimming.

*Radial Adjustment Ring: By depressing a locking button on the head, the operator can rotate the adjustment ring. Each "click" typically represents 0.1mm (0.004") of length.

*Self-Locking: Once the adjustment is set, the mechanism locks automatically. This ensures the punch length never "drifts" during long production runs or high-impact nibbling.

*Extended Grind Life: FAB 2 tooling is engineered to allow up to 4.0mm to 5.0mm of total regrind, nearly double that of original style A-station tools.

3. The "One-Touch" Stripper System

FAB 2 assemblies are designed for rapid maintenance.

*Tool-less Changeover: The stripper plate is held in place by a specialized internal clip or "snap" mechanism. Operators can swap out a worn stripper or change to a different hole size in seconds without using a screwdriver or hex key.

*Relieved Design: The stripper is "stepped" to allow the punch tip to extend further, which is what facilitates the extra-long grind life of the punch.

4. Operational Application

The FAB 2 A-Station is the "precision sprinter" of the turret. It is best suited for:

*Complex Patterns: High-density perforated sheets.

*High-Speed Nibbling: Creating smooth-edged contours with small overlaps.

*Thin-to-Medium Gauge: While it can punch up to its tonnage limit, the FAB 2 design is specifically optimized for the heat dissipation required when running at the maximum speeds of modern CNC presses.

Interchangeability: Existing solid punch bodies can be used interchangeably with FAB 2

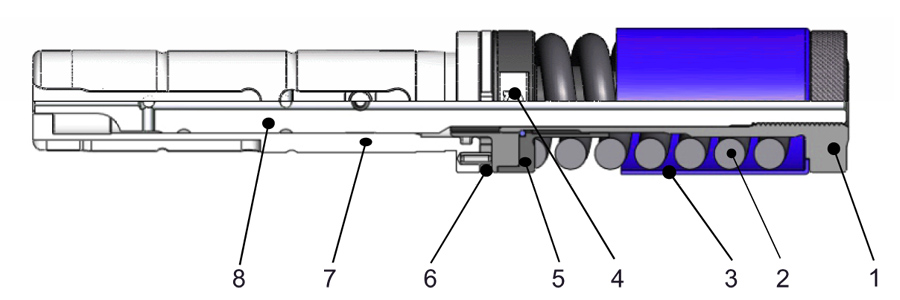

A station Product Structure Diagram

| |

| 1.Punch head 2. Spring 3.Cover 4.Push button | 5.Retainer 6.Index Pin 7.Guide 8.Punch body |

*Max.Allowable Tonnage:6 Tonne *Max.Thicknesss 4.0mmMS,3.0mm SS *Min. Dia/Width: AL 0.75xT,MS 1.0xT. SS 2.0xT *Ejector for size >6mm | Die pin location and shape code

|

Std slot 0-90 deg on guide, optional 0-135 deg

Specifications

| Applicable Punch Body: STD and Air-blow | Maximum Material Thickness: Mild/Aluminum 3.0 mm. |

| Applicable Guide: open guide | Minimum Adjustment: 0.15 mm. |

| Tooling Size: 1/2”. 12.7mm | Punch Height: 207.5 mm. |

| Maximum Tonnage: 45 kN. | Assembly Height: 208.0 mm/209.5mm |

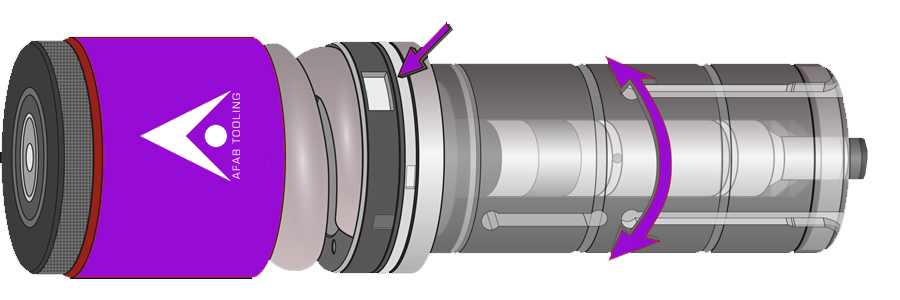

Easy handling without seperate tooling

1.Push the push button (Unlock)

2.Turn guide ⇒ Height adjust longer or shorter

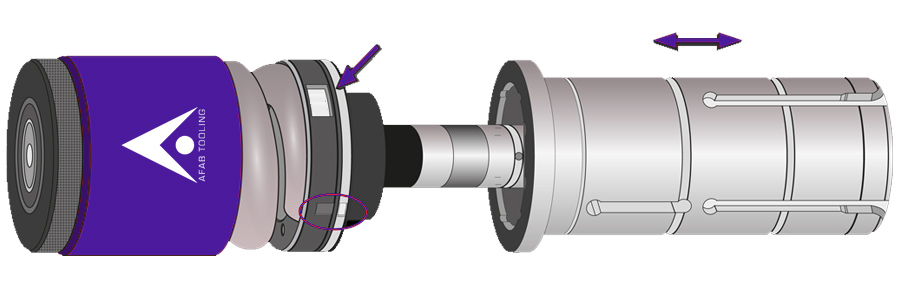

1.Push the push button (Unlock)

2.Turn to match mark positions

3.Pull out guide⇒ Remove guide