| Availability: | |

|---|---|

FAB2 style -Alpha guide assmbly, Z type guide assembly

Its quick adjustment mechanism, extended grinding life, and high-quality materials make it a reliable choice for manufacturers seeking precision, durability, and cost savings. The assembly's compatibility with major OEMs and optional coatings further enhance its versatility and performance

D station Product Features

| |

*Max.force Tonnage:16 Tonne *Max.sheet thicknesss 6.35mmMS, 3.0mm SS *Min. Dia/Width: AL 0.75xT,MS 1.0xT. SS 2.0xT *PU ejector for size >6mm |

|

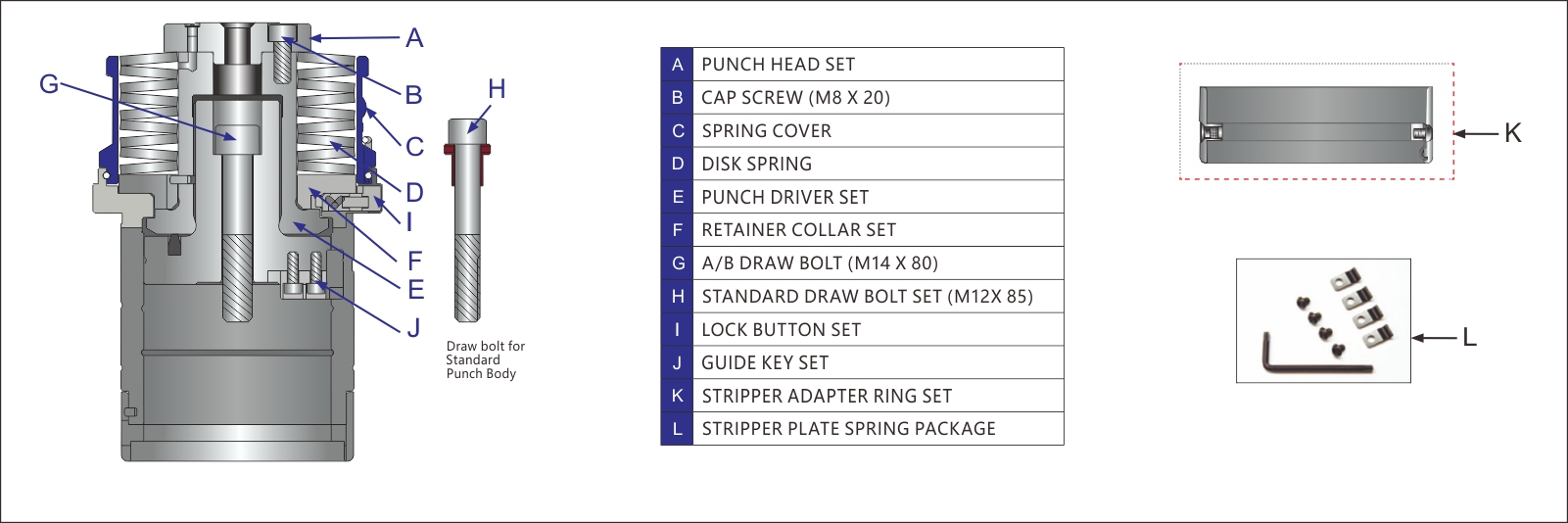

Guide assembly parts name as below chart

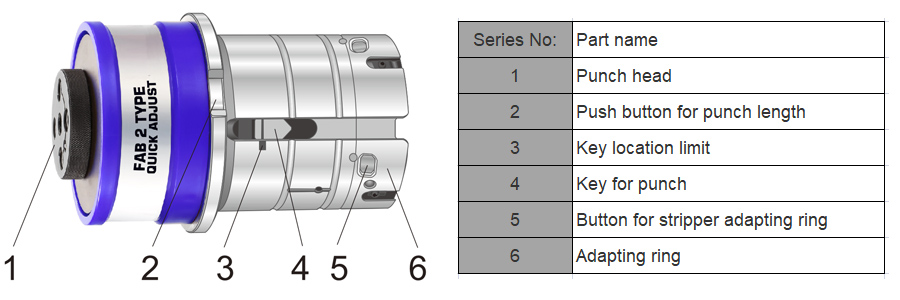

This guide assembly can work for both air blow punch body and standard basic punch body. And the punch

height adiusting can be done very simply,easily

| Max thickness | 6.35mm |

| Max punch capacity | 300KN,30TONS |

| Grinding life | 5mm |

| Punch body | Basic type and airblow,slitting type |

| Stripper | Basic type |

| Mini height adjusting | 0.2mm/1 pitch |

Punch length adjusting: Hold guide,press button 2, turn punch head 1, Punch become longer or shorter. Key 4 not allow over mark 3

Remove adapting ring: Push 4X button 5, turn ring,take out adapting ring 6

Guide assembly feature

1.push-button length adjustment mechanism, allowing for quick and precise punch length adjusting without the need for tools

2.Extended punch grinding life of up to 5-6 mm, reducing the frequency of tool changes and maintenance

3.Guide assembly ensures that all critical areas and surfaces are adequately lubricated during operation. This reduces wear and tear and extends tool life.

4.It equip with original basic punch body, stripper, die. Better interchangeability and versatility

5.The punches are typically made from M2 high-speed steel with a hardness of HRC 60-64, while the dies are made from D2 tool steel with a hardness of HRC 58-60