| Availability: | |

|---|---|

FAB2 style -Alpha guide assembly, Z type guide assembly

A quick adjustment mechanism that allows for rapid punch length adjustments using a push button, and install/remove stripper by button quickly simply.This significantly reduces setup time and increases productivity

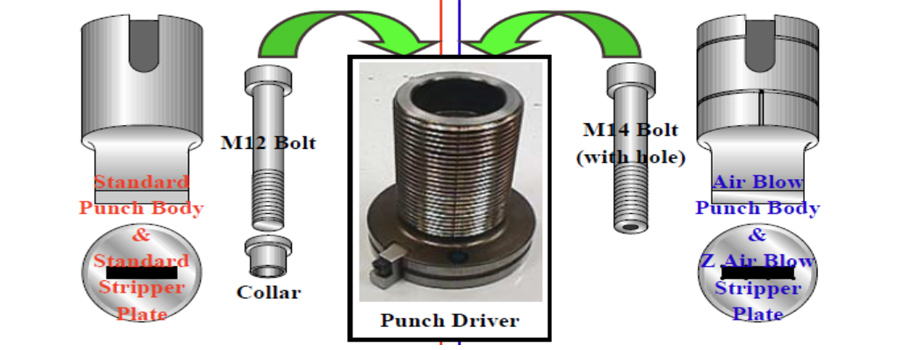

C station Product Structure Diagram

| |

*Max.force Tonnage:16 Tonne *Max.sheet thicknesss 6.35mmMS, 3.0mm SS *Min. Dia/Width: AL 0.75xT,MS 1.0xT. SS 2.0xT *PU ejector for size >6mm |

|

Guide assembly feature

1.Push-button adjust punch length easily, without any tool and shims

2.Punch regrinding life 6.5mm. save lots cost.

3.Lubricate for guide surface. Extend guide life

4.Guide assembly for both std punch M12 bolt+collar and Air blow punch M14

5.Seperate push button to install,take out of stripper

6.It equip with original basic punch body, stripper, die. Better interchangeability and versatility

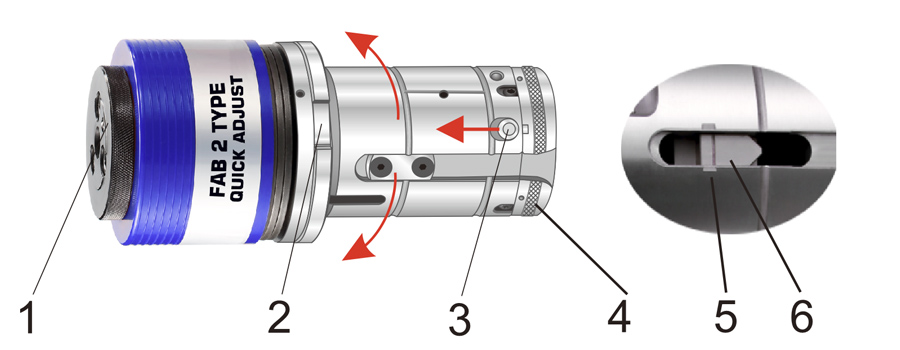

Push button for Guide assembly

Operation

Lenght adjusting: Hold guide,press button 2, turn punch head 1, punch get longer or shorter. Monitor Key 6 location, mark on key not allow over mark 5

Stripper remove: Hold guide,push button 3 towards to punch head as red arrow, Turn stripper adapting ring 4, take out stripper.

| |||||

| 1.Punch head | 2.Push button for punch length | 3.Button for stripper | 4.Stripper adapting ring | 5.Length limit | 6.Punch key |

Punch Tip and Die Type

|

| |||||||||

| Whisper | Rooftop | Invertrooftop | Concave | 4-way | Standard | Positive | Step | Anti slug1 | Anti slug2 | |

The guide assembly's primary role is to guide the punch accurately during the punching process, ensuring precision and extending tool life. It also plays a key role in the stripping function and often incorporates features like Air-blow capabilities to prevent slug pulling (depending on the machine model).

1. Maximum Regrind Value

Feature: Significantly increases the maximum grindable length of the punch body.

Description: The guide system allows the punch body to be reground by up to 6.5 mm (for materials less than 3.2 mm thick), which is a substantial increase compared to older or traditional tooling.

2. Integrated Air-Blow Compatibility

Feature: Designed to work optimally with the Air-blow tooling system (when available on the machine, such as EM and AC series).

Description: The assembly is compatible with both standard and Air-blow style punches. The Air-blow system supplies air and an oil mist to the guide/punch area.

3.Simplified Tool Maintenance (Quick Assembly)

Feature: Quick assembly and adjustment mechanism (e.g., using a lock bolt and turning the punch body for height adjustment).

ADVANTANGE:

1.Reduced Tooling Costs

By increasing the maximum regrind amount to 6.5 mm, the life of the punch body is dramatically extended. This means fewer punch bodies need to be replaced over time.

2. Minimized Downtime & Maintenance Effort

Advantage: Greatly reduces tooling maintenance time (in some cases, claimed to be reduced to 1/3).

Benefit: Faster tool changes and height adjustments lead to increased machine uptime and overall productivity.

3. Improved Part Quality

Advantage: High-precision guidance minimizes lateral movement (slop) of the punch.

Benefit: This helps minimize "silver's appearance" (a form of excessive wear/galling) and ensures the punch contacts the material with maximum accuracy, leading to cleaner holes and longer-lasting tools.