| Availability: | |

|---|---|

The FAB Ultra Type Thick Turret Tooling is a revolutionary solution designed for high-performance metalworking operations. Crafted with precision and built to last, this tooling is engineered to handle thick materials with ease. The ultra-robust construction ensures durability even under the most demanding conditions. The tooling components are manufactured using top-grade materials that offer excellent resistance to wear and tear. With a focus on accuracy and repeatability, the FAB Ultra Type Thick Turret Tooling is capable of delivering consistent results, making it an ideal choice for precision metal fabrication tasks. The design is optimized for seamless integration with various turret punch presses, providing maximum flexibility and efficiency in production processes.

1. Superior Durability: The use of high-quality materials in its construction gives the FAB Ultra Type Thick Turret Tooling exceptional durability. It can withstand the rigors of heavy-duty metalworking, reducing the need for frequent replacements and minimizing downtime.

2. Precision Engineering: Each component is meticulously engineered to ensure precise positioning and accurate punching. This results in clean and consistent holes, enhancing the overall quality of the finished product.

3. Versatility: It is compatible with a wide range of thick materials, including stainless steel, aluminum, and carbon steel. This versatility makes it suitable for various industries such as automotive, aerospace, and general manufacturing.

4. Ease of Use: The tooling is designed for user-friendly operation. It can be quickly and easily installed and removed from the turret punch press, saving valuable time during production.

1. Automotive Industry: In automotive manufacturing, the FAB Ultra Type Thick Turret Tooling is used for fabricating components such as chassis parts, engine mounts, and body panels. Its precision and durability are essential for meeting the strict quality standards of the automotive sector.

2. Aerospace Industry: For aerospace applications, where precision and reliability are of utmost importance, this tooling is used to create parts for aircraft structures, engine components, and landing gear. The ability to handle thick materials with accuracy is crucial in this industry.

3. General Manufacturing: From metal furniture production to appliance manufacturing, the FAB Ultra Type Thick Turret Tooling finds wide application. It enables manufacturers to produce high-quality metal products efficiently and cost-effectively.

| ||

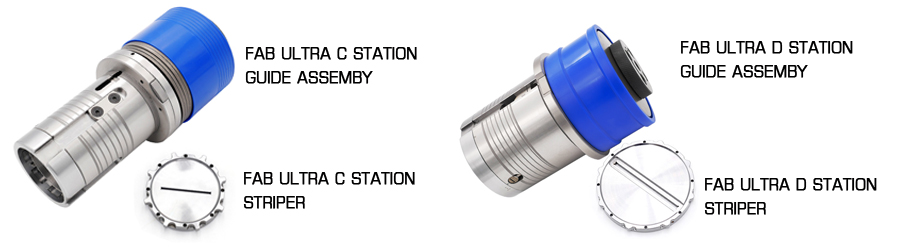

| FAB ULTRA C STATION | FAB ULTRA D STATION | FAB ULTRA E STATION |

FAB ULTRA C D E STATION PUNCH LENGTH ADJUSTING

1.Press the push button 2. Rotate punch head 3.Punch length longer or shorter 4.Release button to get correct length

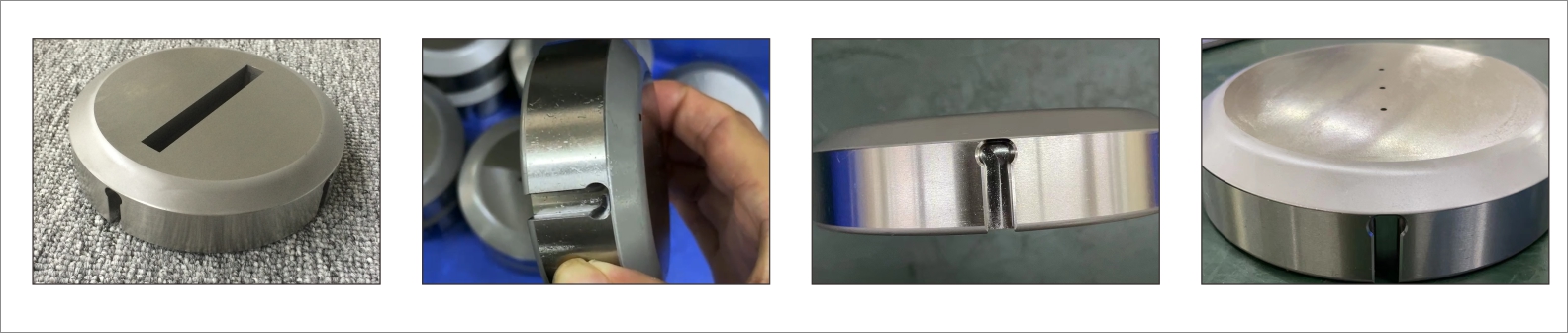

FAB ULTRA CDE STATION STRIPPER SET

1.Install ultra stripper,match pin in guide 2.Put lock ring 3.Rotate lock ring to fix stripper by Clockwise as arrow

CDE STATON VACCUM DIE, Advised to punch cutting size 5X50,5X80,5X100. Keyway designed to enforce strength,avoid die damage

Popular special shape

| ||||||

| Cable connector | Quad R | Keyhole | Keyway | Drum | Trapezoid | Microjoint |

| ||||||

| One way | 4-way | Banana | Connector | Keyhole | Keyhole | Cross |

Punch body available with TICN,TIN,DLC coating.

TiN (Titanium Nitride),TiCN (Titanium Carbo-Nitride),DLC (Diamond-Like Carbon),Punch body coatings are essential for enhancing tool performance, durability, and efficiency. They reduce friction, improve surface finish, and extend tool life, leading to significant cost savings and increased productivity. By selecting the appropriate coating for specific applications, manufacturers can achieve higher quality finished products and reduced downtime

Punch Tip and Die Type

|

| |||||||||

| Whisper | Rooftop | Invertrooftop | Concave | 4-way | Standard | Positive | Step | Anti slug1 | ti slug2 | |