Views: 0 Author: Site Editor Publish Time: 2026-01-19 Origin: Site

In sheet metal fabrication, punch tooling infrastructure is crucial for ensuring efficiency, precision, and cost-effectiveness. The right tooling can drastically improve the overall productivity and performance of a manufacturing process. Punch tooling is a critical component in operations that require high-volume production and precise cuts. Whether you are dealing with thicker materials or need rapid tool changeovers, selecting the appropriate tooling infrastructure is essential. At AFAB, we specialize in providing a wide range of punch tooling solutions such as thick turret tooling, Trumpf tooling, Murata tooling, and Strippit thin turret tooling to meet the diverse needs of various industries. This article will delve into the different types of punch tooling infrastructures, their key features, and how they contribute to enhancing your production processes.

Punch tooling infrastructure encompasses the tools and components required to carry out precise cutting, forming, and shaping tasks within punch presses. These tools are responsible for transforming raw metal sheets into highly specific parts that fit a variety of applications, from automotive to electronics. In essence, the tooling infrastructure defines the capability of the punch press to produce high-quality, uniform results consistently.

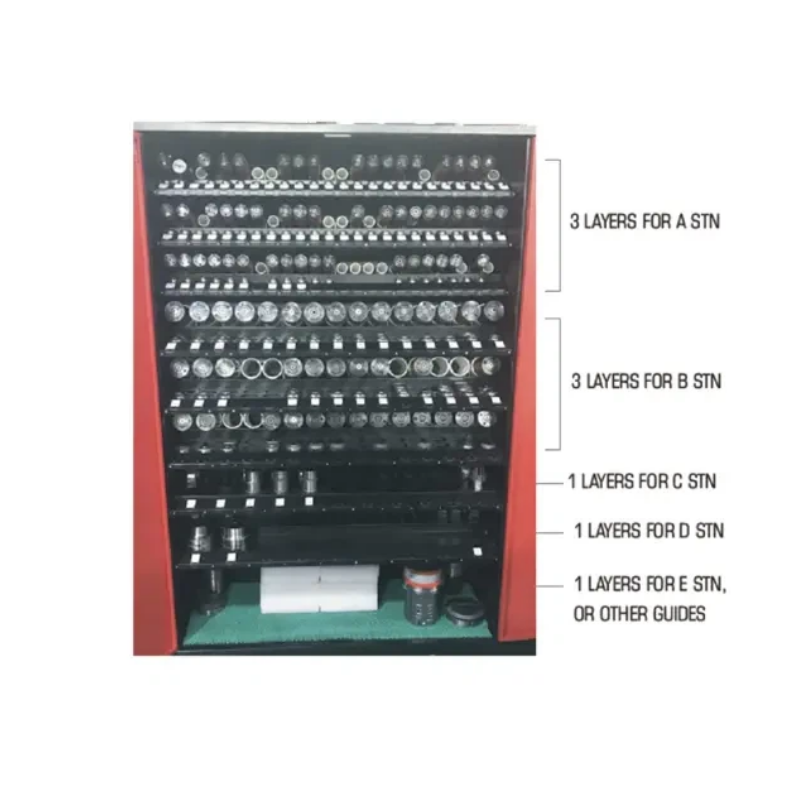

The key components in punch tooling infrastructure include the punch body, die, stripper, and guide. These components work in harmony to perform accurate punching operations. The choice of tooling infrastructure can influence not only the quality of the product but also the cost, time, and overall efficiency of the production line. Selecting the right infrastructure is essential to achieve the desired outcome while minimizing material waste and production downtime.

The turret punch press is a machine that uses a turret mechanism to hold and rotate multiple punches, enabling it to automatically change tools between operations. This allows manufacturers to perform a wide variety of tasks on a single machine, drastically reducing setup times. The CNC-controlled turret automatically switches between tools in response to programmed instructions, improving the speed and accuracy of the punch press.

By offering multi-tool rotation, turret punch presses allow manufacturers to perform different tasks, such as punching, forming, and even shearing, all without manual intervention. The ability to quickly switch between tools ensures minimal downtime and maximizes production efficiency, especially in high-volume environments.

Thick turret tooling is an essential component of punch tooling infrastructure for heavier-duty applications. Designed to support higher tonnage presses, thick turret tooling is ideal for working with thick materials or producing intricate parts that require significant force. This type of tooling is built to last and can handle tough tasks while maintaining precise cutting capabilities.

Robust Construction: Thick turret tooling is made from high-quality, durable materials that ensure longevity and performance. It is specifically designed to withstand the pressures of heavy-duty operations.

High Tonnage Support: This type of tooling is capable of supporting presses with higher tonnage requirements, making it suitable for materials that need more force to be processed.

Versatile Applications: Thick turret tooling is versatile and can be used in a variety of applications, including the cutting of thick sheets, complex forming, and high-tolerance jobs.

Durability: The robust construction of thick turret tooling ensures it remains in good working condition for an extended period, reducing the need for frequent replacements and minimizing downtime.

Adaptability: Whether you're working with thicker materials or intricate designs, thick turret tooling can be adapted to various punching applications, providing flexibility for different jobs.

Reduced Downtime: Because of its durable nature, thick turret tooling requires less frequent maintenance and tool changes, leading to reduced downtime and improved operational efficiency.

At AFAB, we offer several types of thick turret tooling to cater to different press machines and production needs. Our offerings include the Original, NEX, QuickAdjust, and Ultra options. Each of these options provides unique benefits, such as improved adjustability, faster tool changes, and better compatibility with various machine types, ensuring you have the right tooling for your specific production requirements.

Trumpf style tooling is specifically engineered to handle high-speed, high-precision applications. Trumpf tooling is highly regarded in the manufacturing industry for its ability to handle large-volume runs while maintaining tight tolerances. This tooling is designed to provide quick changeovers and deliver repeatable accuracy, making it perfect for production environments where time and precision are critical.

Trumpf tooling is built for rapid tool changes, allowing manufacturers to maintain high production speeds without sacrificing precision. This capability is particularly beneficial for industries that require frequent changes in tooling or those producing parts in large quantities. The Trumpf style tooling also ensures consistent results, even in high-volume runs, making it one of the most reliable tooling choices in the industry.

Trumpf style tooling is best suited for industries that demand high precision and speed, such as electronics, automotive manufacturing, and industrial machinery production. It is ideal for operations where fast tool changes are essential and for environments where production runs involve small to medium-sized parts that require high levels of accuracy.

Murata tooling is a modular, adaptable solution designed for rapid punching and forming operations. The modular design allows manufacturers to adjust the tooling setup quickly and easily, reducing setup time and improving overall production efficiency. This type of tooling is known for its speed and adaptability, making it suitable for various applications that require quick changes and fast punching capabilities.

Thin turret tooling is lightweight and flexible, making it ideal for frequent tooling changes and smaller-scale production runs. This type of tooling is particularly beneficial for operations that need to process thinner materials, such as lightweight metals used in electronics and small parts production. Thin turret tooling is designed for fast changeovers, allowing manufacturers to maximize productivity while maintaining precision.

Below is a comparative table highlighting the differences between various punch tooling infrastructures to help you select the best option for your needs:

Tooling Type | Best For | Material Thickness | Setup Speed | Typical Press Types |

Thick Turret | Heavy duty, multi-form | Thick | Medium | Amada, Euromac |

Trumpf Style | Precision high volume | All | Fast | TRUMPF |

Murata | Fast punching & forming | Medium | Fast | Murata presses |

Thin Turret | Light sheet, fast change | Thin | Very Fast | Strippit / Thin |

The overall performance of punch tooling infrastructure is largely determined by the design and construction of key components such as the punch body, stripper, die, and guide. These elements work in harmony to provide precise, reliable results. The material used in the tooling and the tool wear also play an important role in ensuring optimal performance and maintaining the accuracy of cuts over time.

Each of these components contributes to the punch press's ability to maintain accuracy and consistency. For instance, the punch body directly impacts the force applied to the material, while the die provides the final shape. The stripper holds the material in place, and the guide ensures proper alignment of the punch and die.

The longevity and performance of your punch tooling can be impacted by the materials you work with. Harder materials generally require more durable tooling to prevent wear and tear. By selecting the right tooling infrastructure for your specific material types, you can enhance tool longevity and reduce maintenance costs.

Choosing the right punch tooling infrastructure for your project is critical to optimizing efficiency, reducing costs, and maintaining consistent quality. Whether you are working with thick materials or need to maximize precision, AFAB Tooling provides the right solutions to help you achieve your goals. With our wide range of tooling options, including thick turret tooling, Trumpf style tooling, Murata tooling, and thin turret tooling, we ensure that our products meet the specific demands of your production processes.

Understanding the different types of punch tooling infrastructure available in the market is essential for selecting the right tools for your specific production needs. Each type, from thick turret tooling to Trumpf style tooling, offers unique advantages that can significantly enhance your production processes. Whether you need precision, speed, or adaptability, AFAB Tooling has the right solution for your business. To learn more about our tooling products and how they can optimize your manufacturing operations, visit our product pages or get in touch with us for personalized assistance.

1. What is punch tooling infrastructure?

Punch tooling infrastructure refers to the tools and components used in punch presses to carry out operations such as cutting, forming, and shaping sheet metal.

2. How does tooling structure affect performance?

The punch body, die, stripper, and guide work together to ensure accurate results. The material of these components and their alignment are crucial to achieving high-quality output.

3. Why is precision important in punch tooling?

Precision ensures that parts are consistently manufactured to specifications, reducing material waste and rework while improving the overall quality of the finished product.

4. How can AFAB Tooling help my business?

AFAB Tooling offers a wide variety of high-quality tooling solutions to optimize production efficiency, reduce costs, and maintain high standards of quality. Contact us to discuss how we can support your specific needs.